The world’s first endoscopes with bioplastic material

Raw materials are the largest single contributor to our greenhouse gas emissions and therefore a particular area of focus. In our efforts to lower the carbon footprint of our products, a first step is to use renewable raw material, in our endoscope handles.

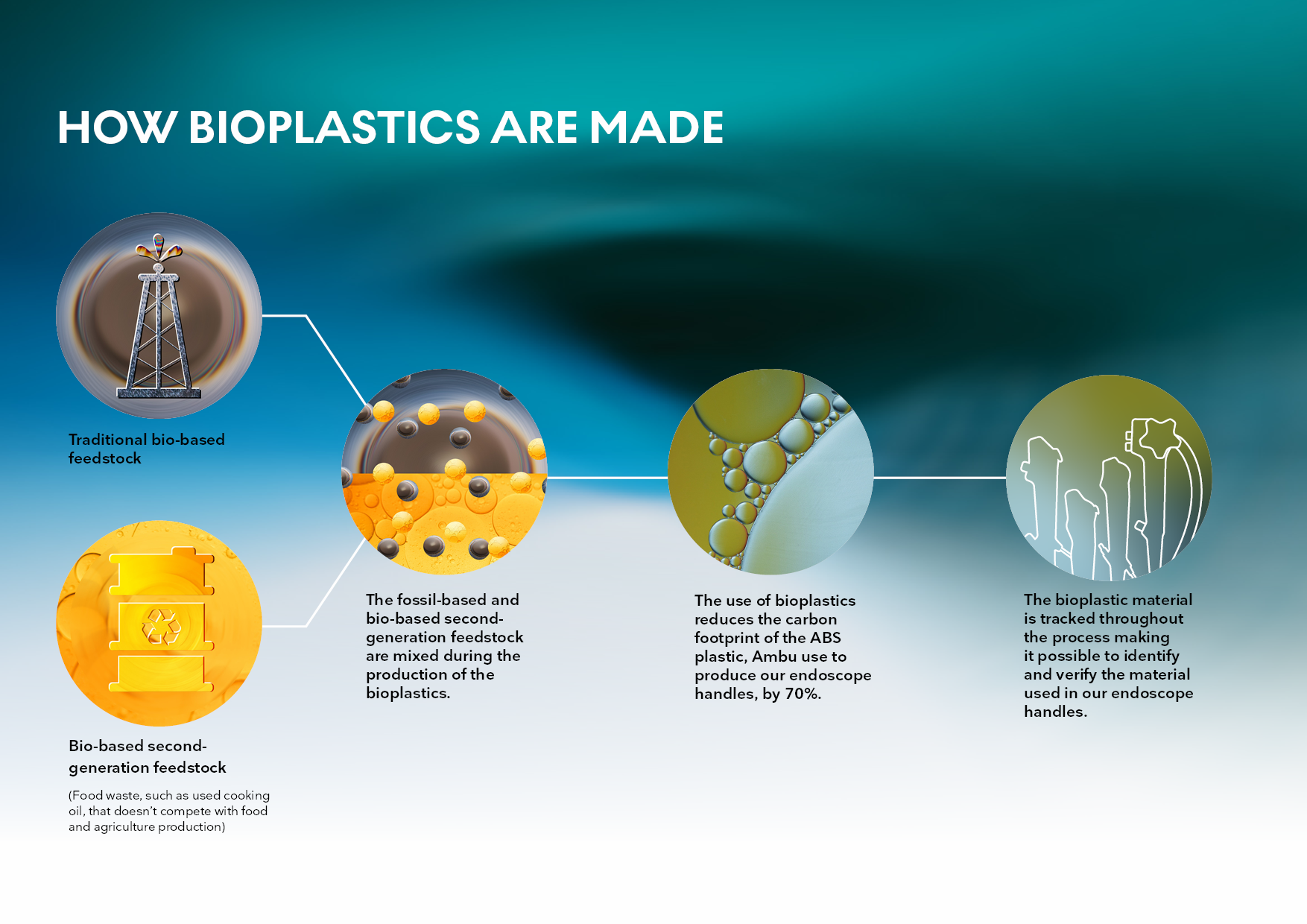

Bioplastic - a more sustainable source of material

Bioplastics are made from second-generation bio-based feedstock mixed with fossil-based raw materials.

The ABS plastic used in the handles emits 70% less CO2 than handles made from purely fossil-based ABS plastic*.

*Based on cradle to gate LCA by manufacturer.

New Packaging Design Lowers our Carbon Footprint

A circular approach to our laryngeal mask packaging has enabled us to:

*When compared to purely fossil-based HDPE plastic.

Our packaging is shrinking

Minimal waste; maximum protection.

The pouches and cuff protectors of Ambu laryngeal masks are designed to ensure that they are in prime condition when you are ready to use them. An equally important objective of our design, however, is to minimise waste.

Get email updates from Ambu

Sign up to our mail list and keep up to date with how Ambu are saving lives and improving patient care. By staying in touch with Ambu you will receive the latest:

- News

- Product updates

- Educational tips

- Thought leadership publications

- Events information

- Exclusive offers